Case study of solving an office floor vibration problem caused by production equipment machinery

In the case of equipment and machinery, vibration problems can suddenly occur in unexpected locations far from the source of vibration due to minor factors such as a change of model or a change in the speed of movement. In such cases, Yacmo's AMD can provide “after-the-fact” countermeasures.

issue

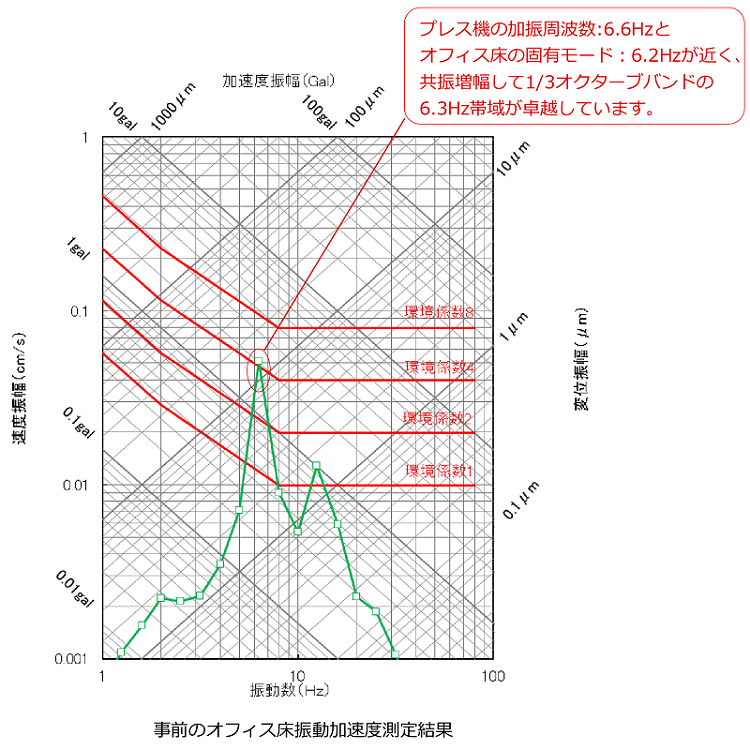

At Company A's plant, when presses operated at high speeds, the floor in the adjacent office building shook significantly, and there was concern that the work environment would deteriorate. Floor vibration measurements showed that the plant almost met the ISO 2631/2 environmental coefficient of 4, the standard for offices, but there were many comments that the shaking was felt by employees when they sat in their chairs and worked, making them feel uncomfortable. Yacmo conducted a more detailed analysis and found that the 6.6 Hz vibration frequency that was particularly large was the vibration frequency of the press, and that the eigenmode of the office floor was 6.2 Hz, which amplified the vibration of the press vibration frequency.

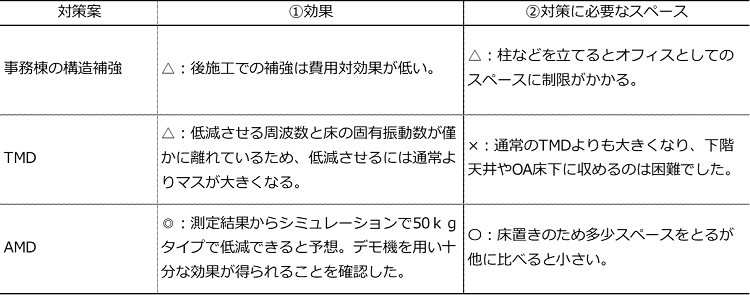

Since the presses were already equipped with anti-vibration measures, it was difficult to take any further measures than those currently in place. The office side measures had to satisfy the following conditions.

- Reduce office floor vibration to an environmental factor of 2.

- Avoid wasting office space as much as possible.

The customer and our company examined various countermeasure methods. As a result, we concluded that the best solution was to install an AMD (active mass damper), a compact vibration control device that can achieve a large effect, because the size of the mass would be too large to reduce 6.6 Hz, which is different from the natural mode of the floor, with a TMD and would not meet the 2 requirements.

counter-measure

The existing 50kg type AMD (YAMD-0050) was customized to make the office space as wide as possible. A total of six units, two for each of the 22m x 40m offices on the 2nd, 3rd, and 4th floors, were to be installed in the center of the span, where the swing is greatest.

result

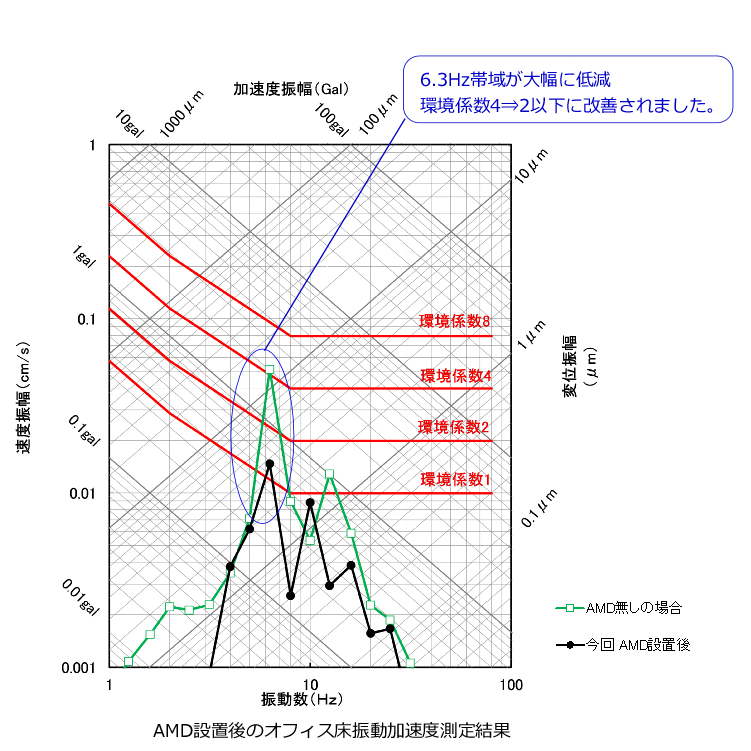

AMD reduced press-derived 6.6 Hz vibration on the office floor. Vibration, which had an environmental factor of about 4, was reduced to an environmental factor of 2 (ISO-2631) or less. The office space was not wasted and the work environment was greatly improved.

Related Pages

- added. This report compares AMD (Active Mass Damper) and TMD (Tuned Mass Damper), which are commonly used as vibration countermeasures for building floors, in terms of features, cost, and ease of maintenance. Please use this report when considering vibration countermeasures.

- Product Information AMD (Active Mass Damper)

Related Content

- Introduction to AMD Series

- AMD Questions Resolved! Frequently Asked Questions Q&A -Floor Shaking Countermeasures

- Types and characteristics of measures to reduce floor sway caused by walking and machinery

- Would you like to diagnose & improve that floor shaking problem with Yacmo's AMD?

- Countermeasure points and improvement examples for machine vibration problems generated from production equipment, etc.