OA floor with seismic isolation function! Ultra-thin seismic isolation floor ~Floor Utena

Floor Utena is a device that has a seismic isolation function attached to the OA floor. It is ultra-thin, easy to install, and has a wider seismic isolation area than conventional seismic isolation floors. The automatic home return mechanism can cope with frequent and repeated earthquakes even after a major earthquake.

Engineering Group, Division 1

Dai Yiqi

Issues in this case study

In anticipation of major earthquakes such as the Great Hanshin-Awaji Earthquake and the Great East Japan Earthquake, many companies have begun to take BCP (Business Continuity Plan) measures. One of the most effective earthquake countermeasures for servers and other important equipment is to install seismic isolation devices.

In this case study, a seismic isolation floor was being considered for the server room and command center in a newly constructed building. The requirements regarding specifications are summarized below.

- Short construction period for a large construction scope.

- The building must be able to be increased or decreased after completion.

- Reduce floor finish height.

(This is a regular office building, not a building dedicated to a data center, and there are restrictions on floor finish height.) - The effective area of the seismic isolation floor must be large, even in a small room.

- Changes in the load carrying capacity due to an increase or decrease in the number of loaded items shall not affect the seismic isolation performance.

Based on the requirements, Yacmo proposed "Floor Utena," an OA floor with seismic isolation. The reasons for each requirement are shown below.

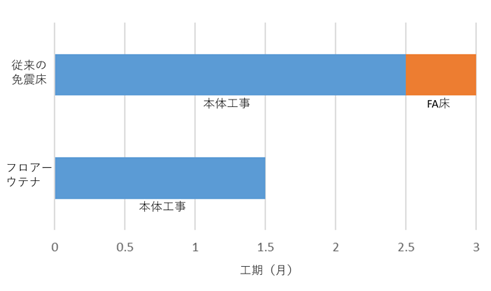

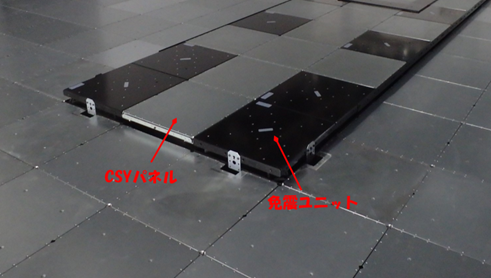

1. Floor Utena is integrated with OA flooring, making it easy to install. As with a normal OA floor, support legs are erected, seismic isolation bearings are placed on them, and they are connected to each other by metal frames. CSY panels are installed between the seismic isolation bearings to complete the installation. In the conventional method, adhesive anchors and level mortar are used, so a curing period is required. In addition, after the seismic isolation floor is assembled, the finished floor (free-access floor, etc.) needs to be installed again, which increases the construction period due to multiple factors. With Floor Utena, however, the construction period is shortened because the main unit can be assembled simply by adjusting the level once after the support legs are glued and fixed. Figure 1 is an example of a comparison of installation time.

Since the building is a unit-type, it is possible to increase or decrease the number of units by replacing floor panels. In this case, after the construction was completed, there was a request for a server expansion, which was accommodated in a short period of time.

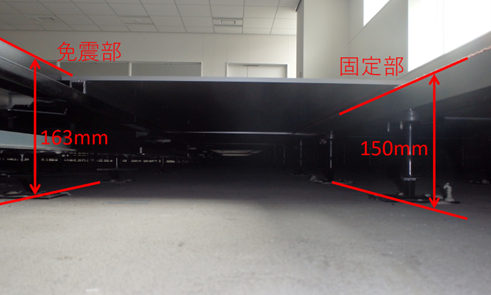

3. Floor Utena can achieve a lower floor height than conventional seismic isolation floors. In this case, the finished height of the seismic isolation floor is only 163mm.

4. Since expansion is not required, the seismic isolation floor area can be large even if the rooms are small.

5. Floor Utena uses FRD (Friction Roller Damper) as a damping mechanism; FRD provides stable seismic isolation performance even when the loaded load fluctuates because the amount of damping changes appropriately according to the loaded load.

In addition, the inclined rail provides an automatic homing function, which can be used for frequently repeated earthquakes even after a major quake.

Special design in this case study

As shown in Figure 2, the Floor Utena produces steps around the seismic isolation section and the fixed section, and the customer wanted to eliminate the steps in some areas.

In order to eliminate steps while maintaining the movement range of the seismic isolation section, an expansion was installed to complete the floor utensil with no steps as shown in Figure 5.

Floor Utena seismic isolation effect

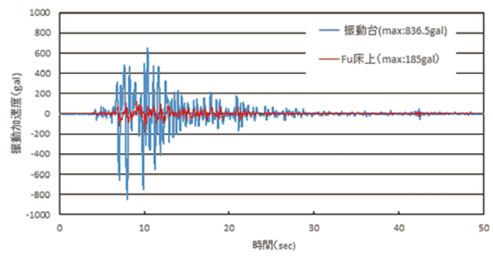

Performance tests were conducted on a vibration test stand to confirm the seismic isolation effect of the Floor Utena. The figure below shows the results of the test when seismic waves in the north-south direction observed during the Hyogo-ken Nanbu Earthquake were input. The results show that the acceleration on the FLOOR UTENA floor is reduced to less than 1/4.

Floor Utena is quietly working today to protect important data and items in case of unexpected major earthquakes.