ACHIEVEMENTS Concerned about floor shaking caused by operating vacuum pumps! Improve the working environment of your factory

vibration suppression equipment

The floor of the plant was shaking due to the vibration caused by the operation of production equipment and machinery installed on the second floor, which was deteriorating the working environment. There were also plans to add more machines, and there were concerns that the problem would worsen further. Therefore, a vibration control system, TMD, was installed to reduce vibration and improve a comfortable working environment.

issue

Production equipment and machinery, such as those installed in factories, are subject to high excitation forces, which often cause vibration problems. Generally, the first floor and foundation slab are not a problem because they are rigid and have low displacement for vibration, but the upper floors are prone to large vibrations due to the low rigidity and mass of the installation site.

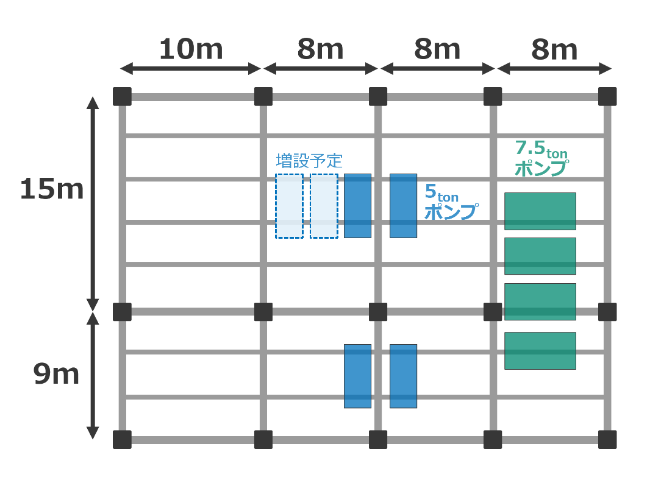

At a certain factory, vacuum pumps were installed on the second floor of a steel-frame structure, which caused the floor to shake significantly during operation, worsening the working environment. There were plans to add a new pump, and there were concerns about further vibration problems (Figure 1).

Figure 1.

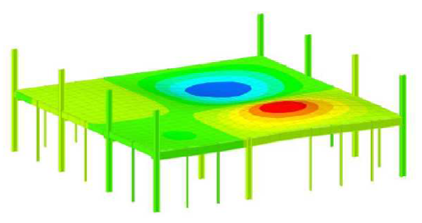

The structural analysis at the design stage also showed that the pump had a natural frequency of 6.9 Hz, and on-site measurements confirmed that the natural frequency was approximately the same. On the other hand, the operating conditions of the installed pumps were 410 rpm (6.83 Hz) for the 5-ton pump and 400 rpm (6.67 Hz) for the 7.5-ton pump, indicating that the operating vibration of the two pumps and the natural frequency of the floor were close and in resonance.

Figure 2: Structural analysis results

counter-measure

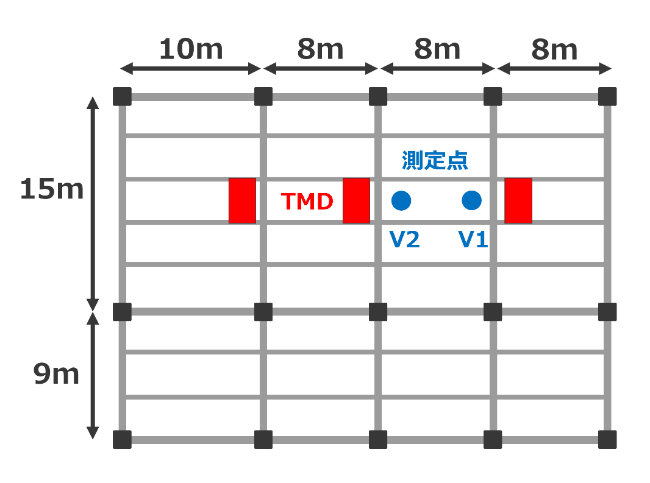

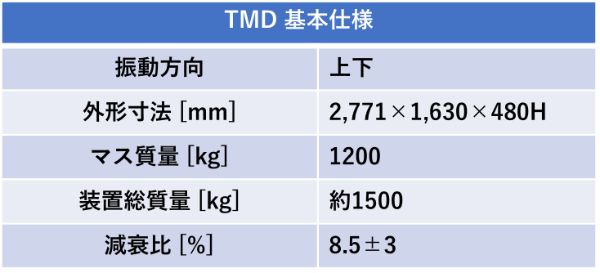

As a countermeasure, three TMDs (mass: 1200 kg) were installed under the floor to reduce vibration.

Figure 3: TMD installation status

Figure 4: TMD installation locations

Table 1: TMD basic specifications

result

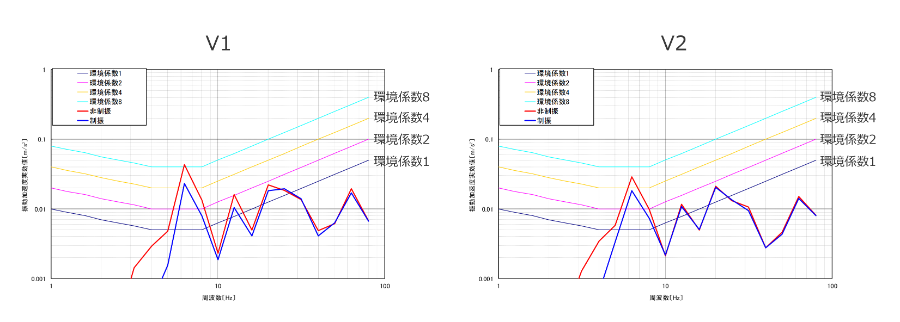

After installation, floor vibration acceleration was measured at points V1 and V2, and evaluation against the ISO 2631/2 evaluation curve showed that it was reduced to an environmental factor of about 4, greatly improving the working environment (Figure 5).

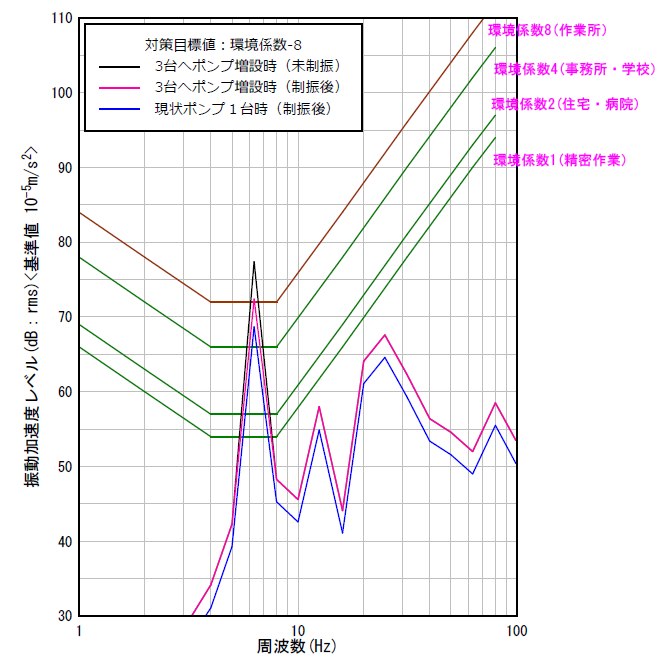

Simulation of the effect after the pumps are added confirms that the TMD vibration control measures will result in an environmental coefficient of about 8, which is a standard for workplaces (Figure 6).

Figure 5: Effects of TMD Floor Vibration Acceleration Measurements

Figure 6: Simulation results of floor vibration acceleration during pump expansion

Related Pages

- added. This report compares AMD (Active Mass Damper) and TMD (Tuned Mass Damper), which are commonly used as vibration countermeasures for building floors, in terms of features, cost, and ease of maintenance. Please use this report when considering vibration countermeasures.

- Product Information TMD (Tuned Mass Damper)

Related Content

- Introduction of TMD Series

- Resolving TMD Questions! Frequently Asked Questions Q&A

- Points and weaknesses of TMD that you need to know in order to achieve optimal results.

- Types and characteristics of measures to reduce floor sway caused by walking and machinery

- Countermeasure points and improvement examples for machine vibration problems generated from production equipment, etc.