Product name

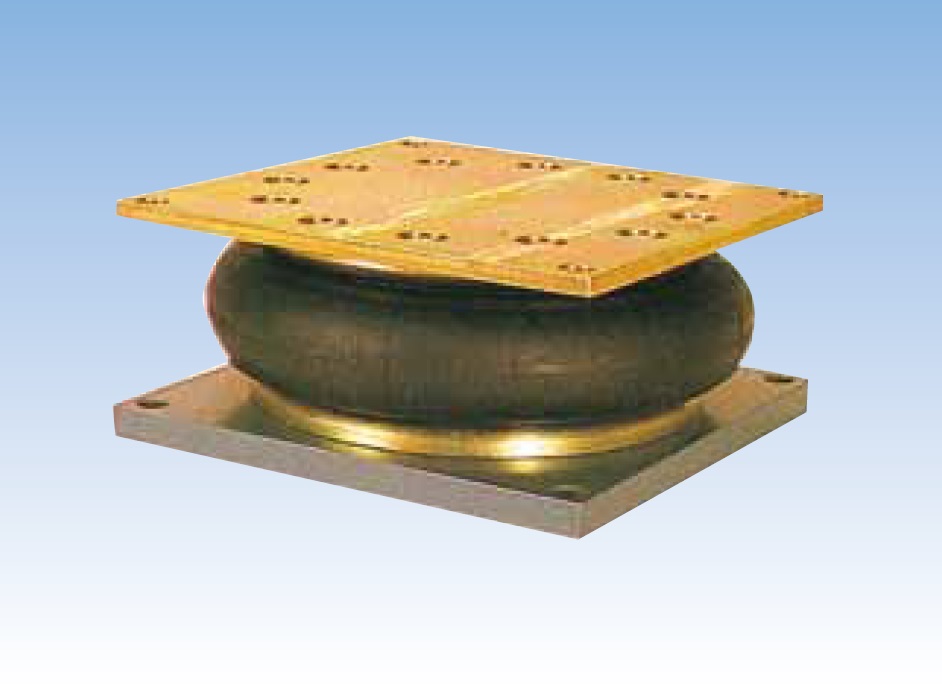

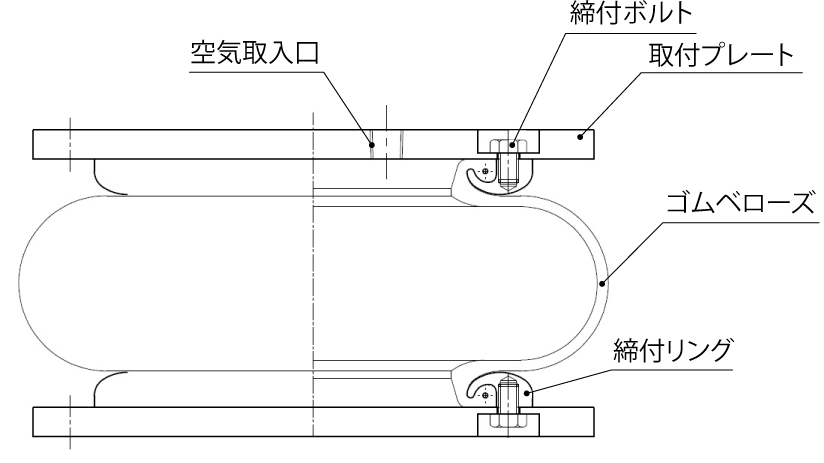

pneumatic spring

model number

Please contact us

forte

- The lineup is abundant (effective diameter φ75 to φ600).

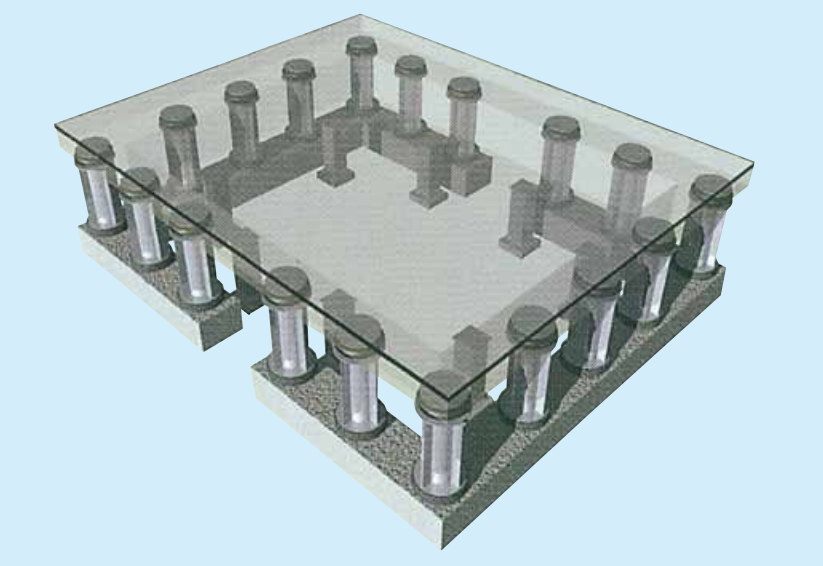

- Compared to coil springs and anti-vibration rubber, it provides superior vibration isolation and high vibration isolation at low vibration frequencies.

- Superior durability compared to coil springs reduces work stoppages due to breakage or failure.

- Air sources are available in factory line piping or with portable compressors.