This section describes how to select the vibration control devices introduced so far according to the application. Since the magnitude of vibration generated by a large-scale earthquake that occurs once every several decades is completely different from that of environmental vibration (wind, traffic vibration, equipment vibration, walking vibration, etc.), the approach to countermeasures is different. This section presents an easy-to-understand guide on how to select vibration control devices for large-scale earthquakes and for environmental vibrations.

Major Vibration Damping Device Features

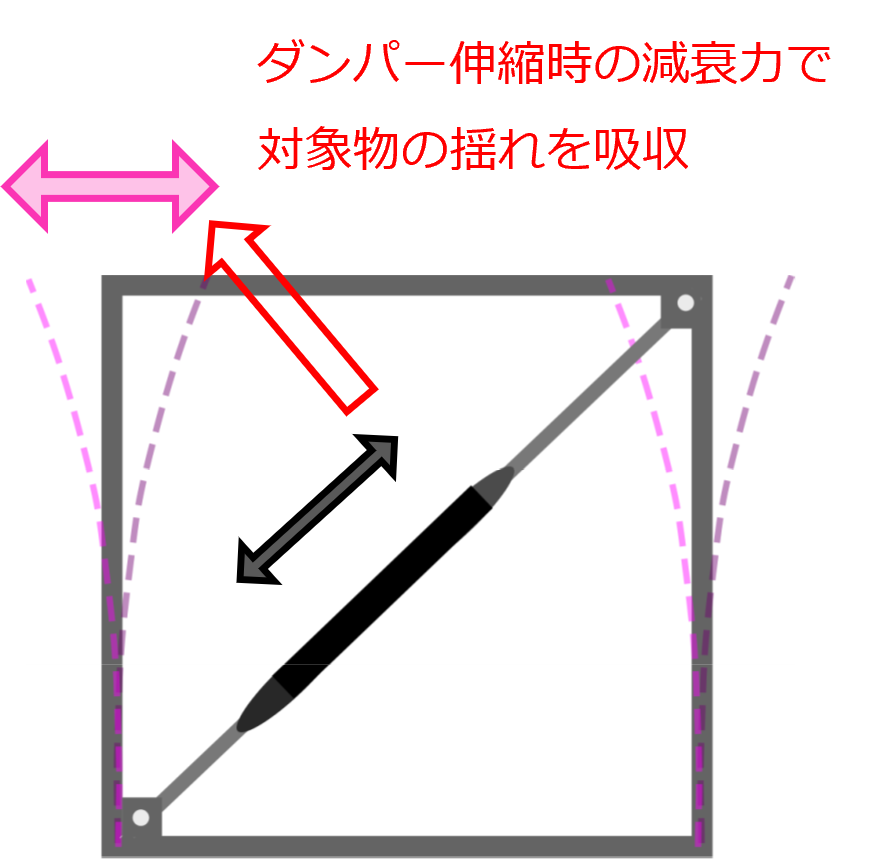

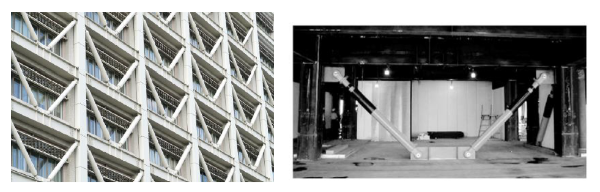

Seismic damper

Bracing materials incorporating oil dampers, etc., are installed on walls and other surfaces to absorb the swaying of the shaft assembly by the damping force of the dampers.

Advantages

- Effective absorption of large energies, such as large earthquakes

- Relatively easy to retrofit to existing buildings

- Maintenance free due to passive system

demerit

- Low effect on minute shaking such as environmental vibration

- May affect the exterior and interior space due to more installation locations.

Fig. 1 Seismic Response Control Damper

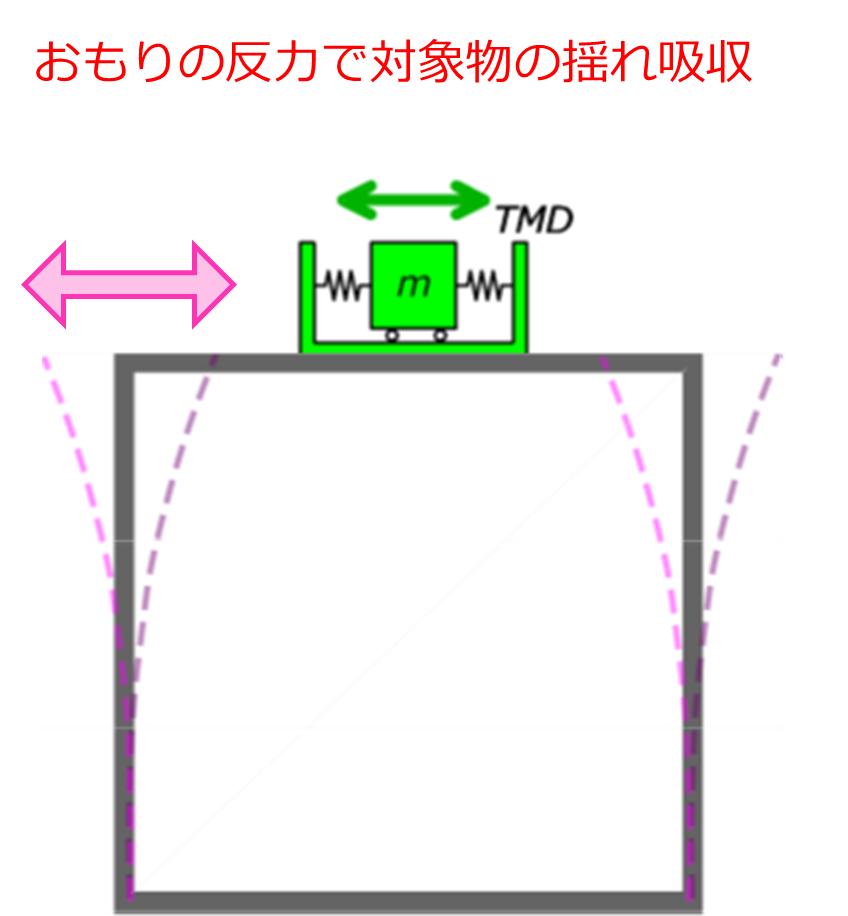

TMD (Tuned Mass Damper))

When a spring-supported weight is attached to an object to suppress shaking, the weight moves and absorbs the shaking of the object. TMDs are vibration-damping devices that utilize this principle.

Advantages

- Maintenance free due to passive system

- Capable of handling both vertical and horizontal vibration (however, separate devices are required for vertical and horizontal vibration)

- If used for seismic applications (which is not often done), equipment can be concentrated on the rooftop, which is advantageous in terms of space

demerit

- Large weights are required. In particular, when designing for earthquakes, very large weights are required, so a rigid floor is needed to support the loads.

- Effective only for specific frequencies that are tuned; separate TMDs are needed for each frequency when there are multiple cycles of oscillation

Figure 2: How TMD works

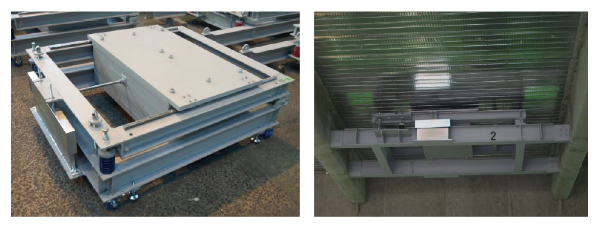

TMD for vertical direction (for floor)

TMD for horizontal direction (for buildings)

Figure 3 TMD (Tuned Mass Damper)

When a spring-supported weight is attached to an object whose vibration is to be suppressed and moves at the same period, the weight reacts and moves well, absorbing the shaking of the object. TMD is a vibration control device that utilizes this principle.

The characteristic of TMD is, as the name suggests, tuning (entrainment); if the period of TMD and the target you want to suppress swaying are out of sync, the effect will not be apparent. If the target has more than one mode (more than one oscillation-prone period exists), the effect will only be obtained for the period in which the TMD is tuned.

*Two types of TMDs are required to produce effects for two modes. Theoretically, the greater the mass of the weight, the greater the vibration control effect, but it is necessary to determine the appropriate mass by prior analysis, taking into consideration economy, ease of construction, and impact on the building.

The photo below shows a TMD (about 1 ton of weight) to reduce vertical sway when walking on a floor or bridge structure. It is usually installed on the beam behind the floor like this.

Figure 4 TMD

AMD (Active Mass Damper)

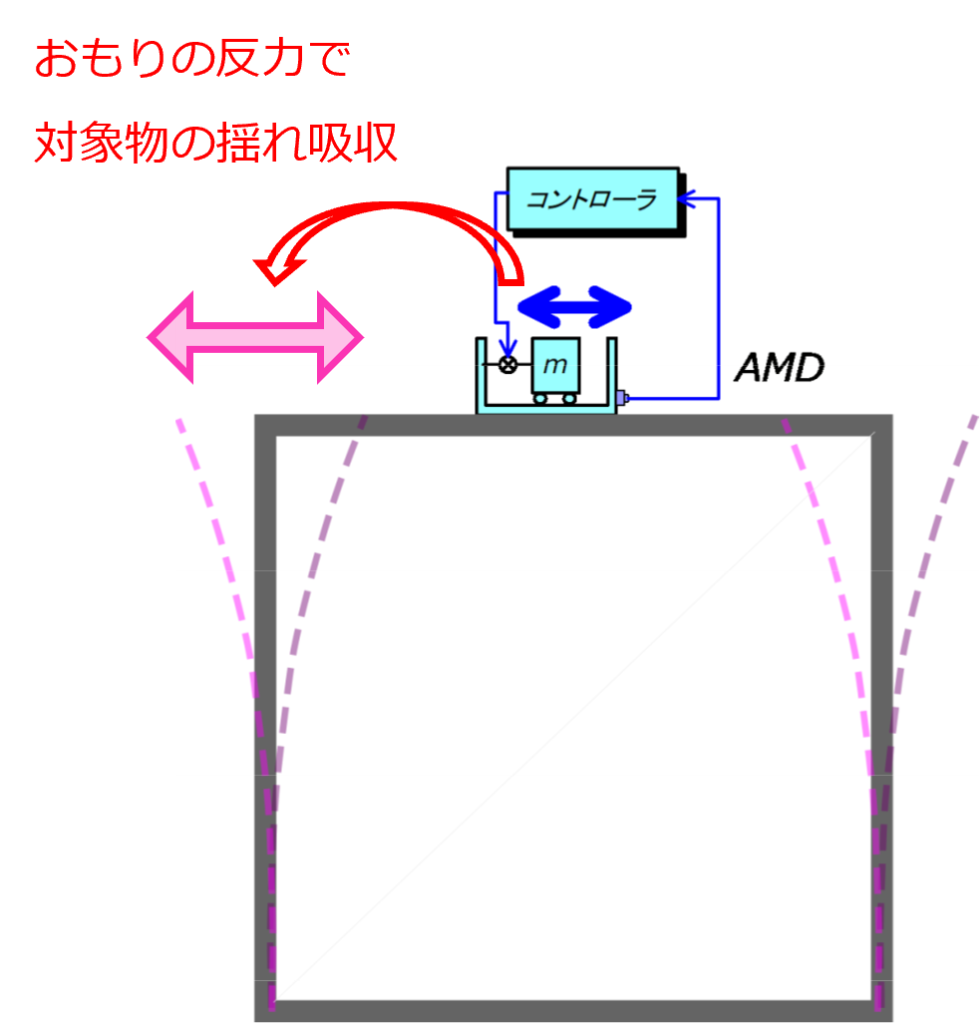

Figure 5: How AMD works

It is the same as TMD in that the vibration is reduced by the reaction force of the weight. Since it is equipped with an actuator (motor or other driving device) and can move the weight as large as desired, it is possible to control the movement through programming to efficiently reduce the vibration of the object.

A much smaller weight than a TMD produces a greater effect and does not require tuning to the object. Also, a single unit can be effective for multiple modes, and can follow changes in the object over time (e.g., changes in natural frequencies).

In addition to TMD, advanced vibration control technology is required. Yakumo is a group of active vibration control professionals! We have a lot of experience in active vibration control, including AMD, and can provide advanced vibration countermeasures.

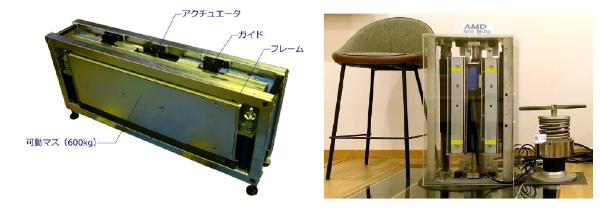

The photo shows AMD for vertical floor vibration (vertical vibration). Left: movable mass 600 kg type, right: 50 kg type, which can be seen in the hands-on showroom.Click here for showroom details

Figure 6 AMD

Vibration Damping (Seismic) Devices Matrix

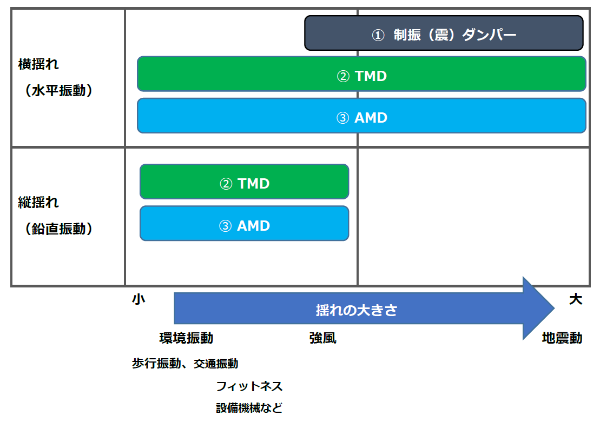

The vibration control devices (1) to (3) introduced here are compared in terms of the range they can cover, using a matrix that divides the target sway into large and small sway x vertical sway/horizontal sway.

AMD and TMD are vibration control devices that can handle both vertical (vertical vibration) and horizontal (horizontal vibration) vibrations, from minute environmental vibrations to large aftershocks such as those caused by earthquakes.

Vibration Damping (Seismic) Devices Matrix